PSI panels are factory-fabricated with all GMAW (Mig) welded connections, performed by Welders who have been Qualified in accordance with American Welding Society guidelines for the specific equipment and materials employed.

We utilize the state-of-the-art “Vertex BD Framer for Light Gauge Steel Program” for our design/material procurement, quality control and labeling procedures for each individual panel. Distributed by Argos Systems, Vertex BD is a highly customizable BIM application continuously employed by PSI since 1999.

Batts Insulation is factory-installed in exterior wall headers/boxed assemblies that otherwise would be inaccessible after fabrication.

Typically, we exclude wall insulation, drywall and all finishes from our bid. Structural (non gauge-metal) Steel is also excluded, except for members which can readily be integrated into the wall panel installation.

Submittals

We employ a two-part submittal process.

First, an overall engineering submittal is made, including Design Criteria and calculations in an 8 ½ x 11 format, as well as (24 x 36) Plans, Sections & Details. Second, we prepare all the individual panel elevations and site layout plans which are submitted for record following approval of the Engineering Submittal.

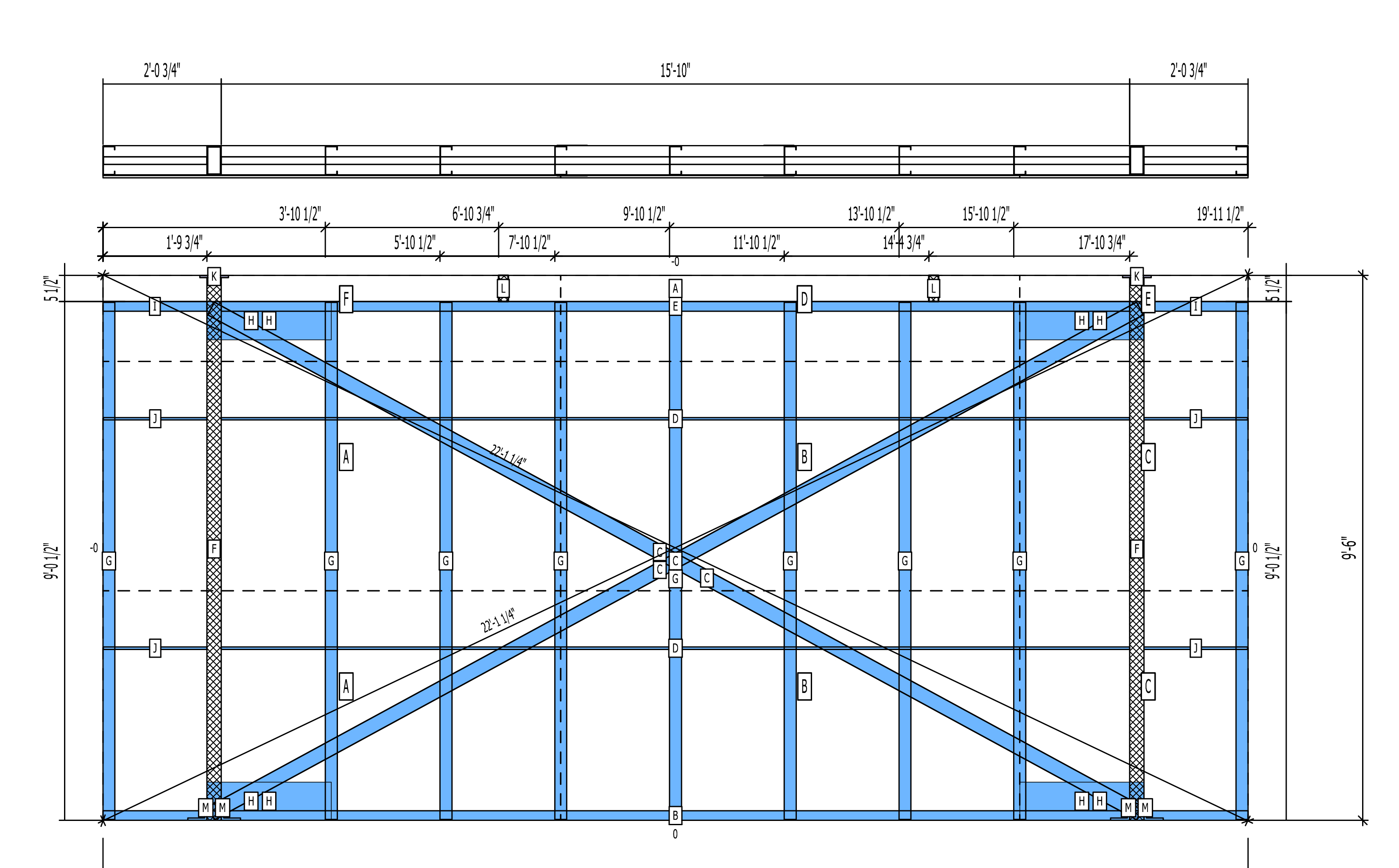

Lateral Bracing Design

The SER defines load paths in the structure, in accordance with the “AISI Code of Standard Practice,” PSI will then design each Shear Wall accordingly. It is assumed that the SER will designate an adequate quantity of Shear Wall locations to allow the use of Light Gauge Straps for the Typical conditions. (PSI is capable of integrating Structural Steel Posts and/or “K-Frames” at select conditions).

Bridging-Bracing

Horizontal Bracing in the Panels is designed to incorporate the latest AISI requirements including diagonal members to “brace the bracing.” Our standard Horizontal Bridging technique, (for studs up to 6”) thick, is to thread 16 ga.

Cold Rolled Channel (CRC), through “punch-outs”and weld the flanges to the studs.

Blast Resistance & Progressive Collapse

Panelized Light Gauge Framing lends itself well to these new structural requirements for Government Buildings. Enhanced Jambs, Sills, Headers and Slab Connections around openings, help meet blast design requirements.

Proper bottom-chord bracing and reinforcing fabric in concrete decks afford the necessary strength to resist upward blast pressures. Continuous HSS distribution plates, rebar, and vertical straps provide the horizontal and vertical ties required to prevent progressive collapse.

LEEDS Considerations

Cold-Formed Metal Framing is a 100% Recyclable product. Under Leed-NC standards, Total Points Available are 69, with Platinum Certification requiring a minimum of 52 points. Local manufacturing plants and low product weight minimize the “carbon footprint” of shipping.

Fabrication, Delivery & Installation

PSI manufactures and installs its own Wall Panels. Field Welders are trained and Qualified per AWS Standards. We utilize a custom designed Quality Control program for every panel. We have the experience and equipment to guarantee on-time Deliveries and Installation in accordance with the strictest Safety & Scheduling standards.